Why is it important to determine the sediment in crude oil by membrane filtration?

A knowledge of the sediment content of crude oil is important both in refinery operations and in crude oil commerce.

Summary of the test method

A portion of a representative crude oil sample is dissolved in hot toluene and filtered under vacuum through a 0.45-μm porosity membrane filter. The filter with residue is washed, dried, and weighed to give the final result.

Why should you use a Tamson set-up ?

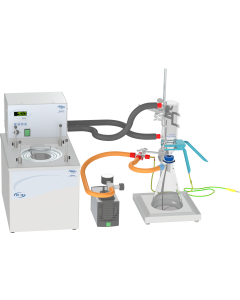

Tamson TC16 circulator pumps the bath content filled with silicon oil through the jacketed (double wall) funnel to maintain the crude oil sample mixed with toluene at 90°C. Necessary filter support, clamp, rubber stopper, 1000 mL vacuum filtering flask, glass T-piece with ground wire, insulated tubing with connectors, stand with clamps, membrane filters, and a vacuum pump are all included in our apparatus. The well insulated and robust TC16 liquid bath has a temperature range from ambient +5°C to 250°C. With the use of our special designed jacketed funnel, safe operating of this ASTM D4807 method is guarenteed and this is a huge and very important advantage. Another important feature is that all parts are grounded. Bath, support and funnel are grounded. A braided wire grounds the flask and sample in the vacuum filtering flask.

Please contact our sales team (sales@tamson.nl) to get a quotation. Or visit our webshop to get price and technical information of a Tamson apparatus to determine sediment in crude oils by membrane filtration conform to ASTM D4807.